Introduction to Generator I

5. Generator Cooling

A generator operates with a high magnetic field and a high current density producing unwanted heat, due to copper losses in the conductors (both rotor and stator) and due to iron losses in the iron core. This heat must be removed or the insulation will be damaged and failure of the generator will occur. As the size of the machines increases so too does the amount of heat generated and requiring to be dissipated.

Industry standards define the maximum allowable temperatures for stator and rotor windings, and these standards tend to limit the size of the generator, dependent on their means of cooling.

In order to produce generating sets with a high power output and a relatively compact construction, manufacturers have been forced to devise more effective cooling systems.

Generator Hydrogen Cooling and Supply System

Characteristics of Hydrogen as a Cooling Medium

Around 1937 hydrogen became the cooling gas universally used in larger machines. Compared to air, hydrogen has a relative specific heat that is 14 times better and a relative density that is 4 times less. In addition, pressurised hydrogen is a better insulator than air, and hydrogen is not an oxidising agent. Helium was considered for cooling but its relative specific heat is only 5 times better than air and its cost is five times more than hydrogen. Helium gas is not available in abundance. There is a concern for hydrogen fires which air and helium does not have. However, in a nearly pure state (>90%) hydrogen does not support combustion. With proper operation, fire hazards are all but eliminated as evidenced by the operating record of utilities in the

The function of the Hydrogen Gas System is to provide high purity, dry hydrogen gas to act as a cooling medium within the Gas Turbine Generator Frame.

Hydrogen gas has a higher thermal conductivity and heat transfer coefficient than air but a much lower density, (7.00:1 1.35:1 and 0.07:1 against air in each case) therefore it acts as a much better heat transfer medium than air when applied to cooling the internal components of the generator.

In addition, pressurized hydrogen is a better insulator than air, and hydrogen is not an oxidizing agent.

The heat transfer capability of the hydrogen gas is increased if the mass of the gas is increased for a given volume. The gas is therefore normally supplied to the generator at a pressure of between 200 to 400 kPa.

Hydrogen Gas Safety

In considering hydrogen as a cooling medium there was a concern for hydrogen fires, a concern, which air and helium did not share.

Helium was considered for cooling but its relative specific heat is only 5 times better than air and its cost is five times more than hydrogen. Helium gas is not available in abundance.

It was considered that, providing adequate safety precautions were maintained, hydrogen could be used effectively in an enclosed cooling system.

Hydrogen Gas forms an explosive mixture with air in concentrations between 5% and 70% Hydrogen.

The intensity of the explosion caused by ignited hydrogen/air mixture varies proportionally, having zero values at 0% and 70% Hydrogen.

The actual pressure of the gas mixture also affects the intensity of an explosion should one occur.

To ensure that a condition does not occur that will create a possible explosion and to reduce the intensity of the explosion, should one occur, the following precautions must be carried out:

• During the purging phase the pressure within the generator frame is decreased to 10 to 20 kPa.

Components of the Hydrogen Gas System

The components of the Hydrogen Gas System include the following:

• Hydrogen Dryer

• Gas Pressure/Purity Monitoring Unit

• Carbon Dioxide Supply

• Supply and Vent Valves and Pipework

• Hydrogen Circulating Fan

• Water/Oil Leakage Detectors

Hydrogen Gas Supply

A makeup supply of hydrogen gas must be available to the hydrogen cooling system to allow the pressure and purity of the hydrogen gas to be maintained while ever the generator is in service and/or filled with hydrogen.

Makeup supply is normally taken from storage banks of compressed hydrogen bottles connected to supply manifolds.

The storage bottles themselves may be replenished by an external supplier or refilled from hydrogen generating plant located on site.

The supply pressure from the hydrogen bottles to the alternator frame may be automatically regulated by a manually set pressure regulating valve or, alternatively, by a reducing valve provided in parallel with the pressure regulating valve.

The pressure of the storage bank and the pressure downstream of the pressure reducing station are normally monitored.

Hydrogen Gas Dryer

The dewpoint of hydrogen within a generator is normally maintained in the order of –25° C in order to prevent internal moisture generated corrosion and failure. This would normally necessitate the inclusion of a hydrogen dryer as part of the hydrogen system.

A number of types of dryer are available in the industry, heatless, regenerative dryers, desiccant dryers, and refrigerant dryers. Any one of these could find an application as a hydrogen dryer.

Within the generator frame, the hydrogen circulating fans create areas of low and high pressure at their suction and discharge respectively.

By locating the hydrogen dryer supply and return pipework between the high and low pressure sections of the generator frame a gas flow is induced through the dryer whenever the alternator shaft is rotating at synchronous speed and the shaft mounted circulating fans are in operation. Unless a dedicated circulating fan is incorporated into the dryer circuit drying cannot take place with the generator out of service.

Maintaining Hydrogen Gas Purity

Maintaining hydrogen gas purity is of paramount importance and the purity of the hydrogen gas within the generator frame is normally monitored by passing a sample of the gas through an analyser.

As carbon dioxide is used as an interfacing agent when gassing up and degassing the generator, it is most common for the analyser to have several functions and to be able to monitor hydrogen purity and the concentrations of hydrogen and carbon dioxide in air.

The suction side of the analyser can therefore be connected to either of two suction lines, one taken from the upper portion of the generator and used for hydrogen purity analysis during hydrogen filling ,the other, taken from the bottom section of the generator and used for analysis of the gas purity while CO2 is being used as an interfacing medium between hydrogen and air.

During normal operation the lower detection point should be used as lower purity hydrogen will tend to be more dense than high purity hydrogen and a reduction in purity should be evident first in the lower portion of the frame.

Although different limits may be placed on purity at different power station sites hydrogen purity should be maintained above 93%.

During normal operation of the generator the small amount of seal oil migrating into the generator frame may carry some entrained air and moisture with it. This air and moisture will be released from the seal oil as it migrates to the defoam tank and will eventually cause a deterioration in hydrogen purity. In order to maintain hydrogen purity it may be necessary to bleed off a portion of the gas while making up the gas volume with pure hydrogen from the cylinder bank.

In some installations a constant, regulated bleed is maintained through bleed lines directed to atmosphere through a flow regulating valve, an oil mist separator and a flowmeter.

Carbon Dioxide Supply

Carbon Dioxide is used as an inert interfacing agent when filling the generator frame with hydrogen or air.

The Carbon Dioxide Supply usually consists of banks of storage cylinders attached to a supply manifold. The storage cylinders may be replenished by an external supplier or by a bulk carbon dioxide facility within the station site.

It should be noted that the gas discharge pipework temperature can be below freezing point and contact between skin and the pipework may result in the skin freezing to the pipework causing frost bite injury to the affected area. Appropriate safety precautions should be taken during operation of this equipment.

During purging the introduction of carbon dioxide may be allowed to cease once the carbon dioxide reaches a purity <75%. The detection of carbon dioxide purity must be taken from the upper sampling point in the generator frame.

Hydrogen Gas Cooling Circuit

The hydrogen cooling circuit includes paths through the stator and rotor windings (see previous diagram of air cooled circulation paths) where heat is gained and a path through the hydrogen coolers where heat is dissipated. To ensure a positive flow through the circuit two fan impellers are mounted on the generator rotor shaft and each draws a portion of the hydrogen from the cooler and passes it through the generator windings and back to the windings. This circuit creates a high and low pressure area within the generator frame while ever the machine is operating at rated speed.

The hydrogen dryer takes advantage of the two different pressure zones to establish a hydrogen flow through the drying chamber.

Banks of hydrogen coolers are normally provided at the side or top of the generator frame. The cooling medium is normally high quality demineralised water from a closed cooling water system.

Contamination of the Generator frame can occur due to a failure of the hydrogen coolers, causing a water leak into the frame, or failure of the hydrogen shaft seal allowing oil ingress into the frame. In either case leakage must be detected. Detection points are normally tapped into the generator frame at each end of the generator adjacent to the seals. These detectors should be regularly checked and the quantity and type of liquid found in them should be logged.

System Monitoring and Alarms

The following parameters associated with the hydrogen gas system would normally be monitored:

• Hydrogen Gas Purity

• Hydrogen Gas Pressure

• Hydrogen Supply Bank Pressure

• The Amount of Lliquid within Liquid Detectors

Hydrogen Sealing System

The generator rotor shaft ends of a hydrogen-cooled generator must be brought out of the gas tight enclosure therefore some means must be provided to prevent the escape of gas along the shaft. This function is provided by a hydrogen shaft sealing system, the components of which normally consist of:

• Seal Oil Ssupply System

Sealing Mechanism

Several propriety seal designs are available on the market. These tend to belong to two categories: one of which forms a seal directly against the shaft, the other forms a seal against a face of a collar machined on the shaft.

In both designs, oil is used to place an hydraulic force on the seal, forcing it against the shaft or collar, while at the same time a film of oil is forced into the fine clearance between the seal and the shaft or collar to act as a lubricant and to remove heat generated at the seal face.

The positioning of the seal means that one side is subjected to the pressure exerted by the hydrogen within the alternator frame while the other is normally located within the adjacent bearing housing and as such is subject to the slightly negative pressure exerted on the bearing pedestal. This pressure gradient across the sealing face has the effect of allowing the greater amount of seal oil to pass from the seal face to the bearing housing. A much smaller flow passes through to the generator side of the seal and into the alternator frame.

In seal designs employing a seal ring and shaft collar two oil supplies are provided; annulus oil and face seal oil.

Annulus oil is directed into an annulus in the seal ring and acts as a hydraulic force to drive the seal against the shaft collar. It is important that the annulus oil is supplied first when setting up the seal oil system in order to ensure that the sealing faces mate around the entire seal circumference. If the ring is slightly skewed excessive oil flows will be seen at the seal face. Although the annulus oil is predominantly a hydraulic medium a small flow is allowed to be bled from the annulus to prevent overheating of the oil at the seal.

As the function of the annulus oil is to maintain a hydraulic force on the seal its pressure is regulated to maintain a set positive differential between itself and the hydrogen pressure within the alternator frame (Annulus Oil pressure > Hydrogen pressure). Annulus oil pressure will therefore vary considerably during periods when the gas pressure is allowed to increase or decrease.

The Face Seal Oil is used as a lubricating and heat dissipation medium. The pressure of the face seal oil is constant.

In seal designs employing a seal directly against the face of the shaft a single oil supply is provided. This supply acts both as the hydraulic medium and the lubricant for the seal. As such this oil supply is regulated to maintain a set positive differential between itself and the hydrogen pressure within the alternator frame.

Figure 20: Typical Seal Design Employing a Seal Directly Against the Shaft

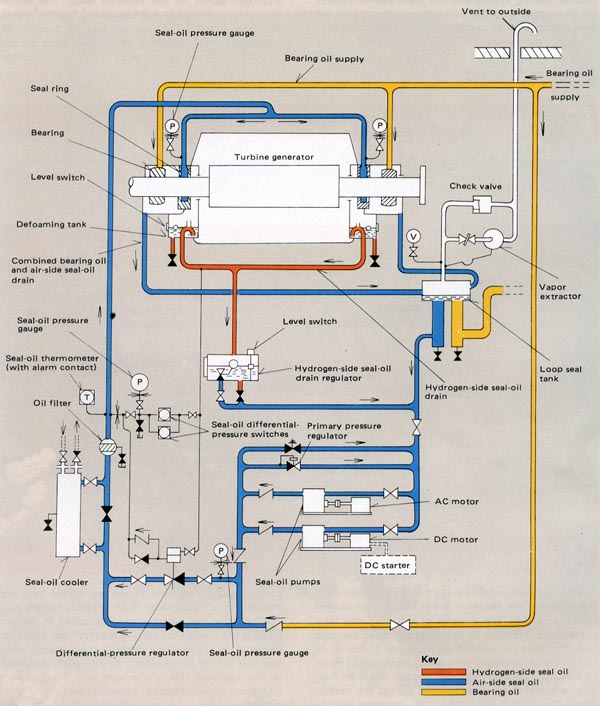

Seal Oil Supply

The function of the seal oil supply is to provide moisture and contaminant free oil at a regulated pressure to the hydrogen seals.

The oil used in the seal oil system is generally drawn from the main lubricating oil system with the pumps either drawing directly from the main lubricating oil tank or from a separate seal oil tank taking its initial and make-up supply from the main oil tank.

The need to maintain the seal oil system in service while ever hydrogen gas (or Carbon Dioxide) is contained within the alternator frame demands that the seal oil pumps must be provided with a degree of redundancy. This usually means that an ac motor driven pump is provided for normal and standby duty while a dc driven pump is provided for emergency.

The seal oil pump discharge is regulated, as required, to maintain the pressure above the design maximum hydrogen gas pressure allowable within the alternator frame.

In designs demanding a separate annulus and face seal oil pressure the face seal oil pressure is regulated at a constant pressure while the annulus oil is regulated to maintain a positive pressure differential over the hydrogen pressure.

Prior to reaching the shaft seal the seal oil passes through a heat exchanger dissipate heat from the system and to maintain a set oil supply temperature (changes in oil temperature and viscosity will effect the performance of the seal).

A filter is provided in the seal oil supply line to remove particulate contaminants.

Seal Oil Return

The oil returning from the seals takes two independent paths, the majority returns through the bearing side drain while a minor amount returns from the hydrogen or generator frame side of the seal.

Oil returning from the bearing housing side of the seal passes to a loop seal oil tank before returning to the seal oil pump suction side (or main oil tank). A vapour extraction fan is connected to the loop seal to maintain the bearing housing under a negative pressure and to remove any oil vapour or hydrogen present within the bearing housing.

The oil returning from the alternator side of the seal may have hydrogen gas entrained within it, therefore this oil is passed first to a defoam tank before it is allowed to mix with the oil returning from the bearing side of the seal.

The function of the defoam tank is to allow the small quantity of oil returning from the frame to settle for a period of time during which the hydrogen gas is detrained from the oil. The flow of oil from the defoam tank is regulated to maintain a constant level of oil within the tank. This is done to form a seal between the alternator frame and the seal oil pump suction pipework. Should the seal within this tank be lost the frame can connected to atmosphere through the loop seal oil tank and associated vapour extraction fan resulting in a major loss of hydrogen to atmosphere.

Liquid Detectors

Should the shaft seal face be damaged, allowing excessive flow of oil to the hydrogen side of the seal a condition could exist in which oil overflows from the internal drainage system to the alternator frame.

Liquid detectors with alarm contacts are fitted to the lower sections of the alternator frame to initiate an alarm should a quantity of oil or water be detected.

Seal Oil System Monitoring and Control

Devices within the seal oil system normally monitor the following:

• Seal oil pump discharge pressure

• Seal oil to hydrogen differential pressure;

• Seal oil supply pressure pressure to each seal (face and annulus on ring and collar type seals);

• Seal oil temperature at the cooler exit;

• Seal metal temperature;

• Defoam tank level;

• Vapour exhaust fan suction pressure (vacuum gauge).

The seal oil system should be placed in service before hydrogen is admitted to the alternator frame and must be retained in service until the frame is degassed to atmospheric conditions. The seal oil system should also be placed in service before the turbine/generator is rotated on barring gear.

Figure 21: A Typical Seal Oil System

Stator Water Cooling

As the output rating of generators increases so the use of water cooling for heat removal in the stator becomes more effective. Stator Water Cooling is additional to the cooling still maintained by hydrogen circulation around the stator and through radial cooling passages within the stator.

In a water-cooled stator, demineralised water is circulated through dedicated pathways built into the stator laminations. The stator cooling circuit passes through the entire length of the stator and is connected to the stator water supply and return manifolds through insulated hoses (PTFE or other suitable plastic).

The stator water system usually consists of the following components:

• Filters;

• Coolers;

• Flow measuring equipment;

• Conductivity monitoring equipment and demineralising unit;

• Stator water head tank and associated pipework.

Stator Water Pumps and Circuit Components

The stator water cooling system is critical for maintaining the generator within the limits of design operating temperatures and would normally demand redundancy in its pumps.

Pumps are usually ac motor driven centrifugal pumps discharging at a head pressure slightly lower than that of the hydrogen pressure contained within the generator frame. This has the effect of allowing gas to leak into the stator water system rather than permitting stator water to migrate into the generator frame.

Small and insidious amounts of hydrogen gas entering the cooling water circuit may be detected by the incorporation of float chambers above the generator inlet and outlet manifolds and at the pump suction. Float operated alarm contacts are made when a set volume of gas displaces the water in the chamber. The frequency of alarms and the amount of gas vented from the system to clear the alarm aids in determining the size of the leak.

Heat from the Stator Water System is dissipated to atmosphere through a heat exchanger. Usually the heat exchangers use lower quality cooling water as the cooling medium. The supply pressure of the auxiliary cooling water is lower than that of the stator water system to reduce the likelihood of stator water contamination if a leak in the heat exchanger occurs.

Stator Water Flow and Conductivity Measurement

In order to monitor the stator water systems performance it is common to include of flow measuring station and a differential pressure monitoring station, which detects leakage within the generator frame and initiates a trip of the generator.

The quality of the demineralised water must be high to prevent current flow through the system. Metal pickup from the stator pipework can result in an increase in conductivity with time. The conductivity of the stator water is normally monitored and the provision of a mixed bed polishing column allows the conductivity to be maintained within design limits.

Phase Isolated Bus (PIB)

A Phase Isolated Bus – PIB (or Isolated Phase Bus - IPB) is one in which the conductors of each phase are enclosed in a separate enclosure (normally tubular) and separated from the adjacent phase conductor enclosure by an air gap.

The enclosures are usually made of rigid metal and the conductors within are carried on insulators to maintain safe clearances.

The enclosures may be served by a system, which provides filtered, dry air as a cooling medium and as a means of pressurising the enclosure to prevent the ingress of dust and moisture.

Phase Isolated Busbars are normally used to provide a conduit to carry the conductors from the generator terminals to the unit or generator transformer.

Figure 22: Phase Isolated Busbars Being Erected on Site